Turntable

Turntable Mod's

19/02/12 11:23

Not so much a "tweak" - more a complete rebuild

My turntable started life 30 years ago as a Rega Planar II

Rega's approach back then was to utilize a simple plinth design that was low in density with a bonded aluminum top that would shed vibrations before they reached the arm and platter. Alas, this design was prone to larger "floor vibrations" and required a substantial stand to effectively isolate it.

Rega's solution was to bolt a metal frame to the wall, which worked well with "brick walls", but with timber-frame construction it failed to provide a complete solution.

Since that design, Rega and other manufacturers have adopted the original simplistic Rega design format, but using materials like MDF to build plinths that are acoustically inert.

Taking a queue from these designs I decided to build a new plinth made of 3 sheets of bonded MDF giving it considerably more mass and superior isolation qualities. The design point of increasing the mass is that any vibrations in the component shelf will not be able to move a high mass plinth, especially when combined with an isolation foot with extremely good absorption properties like Sorbothane, as detailed in the section Component Isolation Foot in this blog

The plinth is supported by three of these feet with a modification to imbed them into the underside of the plinth. The feet have been located such that the points at which the arm and platter bearing are attached to the plinth sits in the "null point" of any residual vibrations.

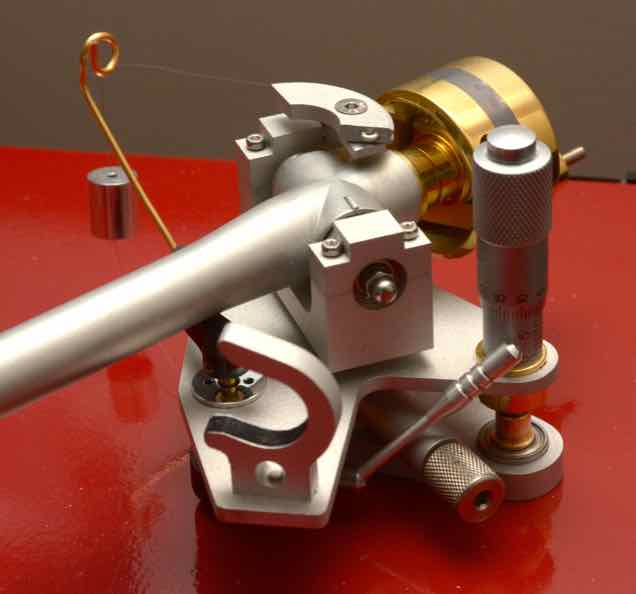

The original "S shaped" arm was originally replaced by a Rega RB250 tonearm, but the latest addition is an Audiomods Series 3 tonearm pictured here. This arm uses the RB250 arm tube and that’s where all similarity to the Rega arm ends!

This shows the micrometer VTA adjustment which allows for repeatable adjustments and more importantly, resetting back to the original state

To round out the tweaks the motor has been replaced with the Rega II Motor Upgrade kit

Installed on the arm is an all time classic - the Denon DL-103 Phono MC Cartridge (standard config - no mod's)

The only original parts left from the Rega Planar II is the switch and the cover!

These "tweaks" have elevated this turntable to a performance level that rivals many higher-end models.

I could have purchased a new turntable for the price I have paid out on these upgrades - but the outcome of this exercise has been very enlightening and increased my knowledge pertaining to the important elements of good turntable design and I feel the turntable performance exceeds any turntable of that price by a considerable margin.

- but the outcome of this exercise has been very enlightening and increased my knowledge pertaining to the important elements of good turntable design and I feel the turntable performance exceeds any turntable of that price by a considerable margin.

So, what improvements did each tweak make?

My turntable started life 30 years ago as a Rega Planar II

Rega's approach back then was to utilize a simple plinth design that was low in density with a bonded aluminum top that would shed vibrations before they reached the arm and platter. Alas, this design was prone to larger "floor vibrations" and required a substantial stand to effectively isolate it.

Rega's solution was to bolt a metal frame to the wall, which worked well with "brick walls", but with timber-frame construction it failed to provide a complete solution.

Since that design, Rega and other manufacturers have adopted the original simplistic Rega design format, but using materials like MDF to build plinths that are acoustically inert.

Taking a queue from these designs I decided to build a new plinth made of 3 sheets of bonded MDF giving it considerably more mass and superior isolation qualities. The design point of increasing the mass is that any vibrations in the component shelf will not be able to move a high mass plinth, especially when combined with an isolation foot with extremely good absorption properties like Sorbothane, as detailed in the section Component Isolation Foot in this blog

The plinth is supported by three of these feet with a modification to imbed them into the underside of the plinth. The feet have been located such that the points at which the arm and platter bearing are attached to the plinth sits in the "null point" of any residual vibrations.

The original "S shaped" arm was originally replaced by a Rega RB250 tonearm, but the latest addition is an Audiomods Series 3 tonearm pictured here. This arm uses the RB250 arm tube and that’s where all similarity to the Rega arm ends!

This shows the micrometer VTA adjustment which allows for repeatable adjustments and more importantly, resetting back to the original state

The original Sub-platter has been replaced by the ISOsub GT 2 S UPGRADE SUB PLATTER and ceramic bearing from Isokinetic. Note: the white spacers in the photo are required to elevate the platter above the central spigot so the platter can be used without a turntable mat. These have since be replaced with three brass spacers, which made a considerable difference in the details retrieved and the smoothness of the overall sound.

The original glass platter has been replaced with an SRM/TECH Deluxe Acrylic Platter for the Rega

- see my SRM/TECH Acrylic Platter Review for more details

To round out the tweaks the motor has been replaced with the Rega II Motor Upgrade kit

Installed on the arm is an all time classic - the Denon DL-103 Phono MC Cartridge (standard config - no mod's)

The only original parts left from the Rega Planar II is the switch and the cover!

These "tweaks" have elevated this turntable to a performance level that rivals many higher-end models.

I could have purchased a new turntable for the price I have paid out on these upgrades

So, what improvements did each tweak make?

- Plinth re-build - provided a much improved soundstage, lower background noise and better details in instruments, together with the near elimination of vibrations to the arm and platter

- Audiomods Series 3 tonearm - huge improvements in fine details of recording venue such as concert hall reverberations and soundstage

- ISOKINETIK Sub Platter - significant improvements in the hi-frequency details and silent bearing operation

- SRM/TECH Deluxe Acrylic Platter - in combination with the Sub-platter the Acrylic Platter has made huge improvements to the details and 3D image to a level I had only heard on turntables costing substantially more.

- Rega II Motor Upgrade kit - near elimination of wow and flutter and much quieter operation