"The HELIX IMAGE" - With a little help from my friends

Last Update: December 2020.

Please see each cable type below for details

This latest development incorporates Neotech Solid UP-OCC Copper wire with Teflon Insulation into all of the Helix Cables

- 12 gauge wire for the Live conductor of the Helix Power Cable

- 14 or 12 gauge wire for the signal conductor of the Helix Speaker Cable

- Two strands of 18 gauge wire for the signal conductor of the Helix Interconnect

The fabrication details and the Neutral wire remains unchanged, which is Silver Plated stranded Copper Mil-Spec wire

I first upgraded the live conductor of a couple of power cables connecting my amp to the mains wall outlet.

The improvements I heard at that time were mainly in the area of improved dynamic performance and more spacious image.

Next was an upgrade to my speaker cables. Based on past versions I decided to use the 14 gauge. in place of the previous 2 x 18 gauge VH Audio wire. Some might prefer the 12 gauge, but I thought this to be too stiff and based on past experiments I had noticed little difference between 12, 14, 16 and 16 gauge wires, with respect to dynamics and bass depth.

Upgrading the Interconnects using the 2 x 18 gauge "Double Shotgun" approach I had employed with the 2 x 18 gauge CH Audio version of the interconnect cables, completed this "trifecta" and highlighted just how good this wire is.

There were improvements to every single metric we use to assess performance -

- Dynamics, Clarity, Details, image size, image focus, space around performers, bass depth and texture

- But there was also a warmth and more body to these cables

- the high frequencies were smoother, cymbals had more texture and vocal sibilance was more "human"

- the mid frequencies had more body and sounded more natural

- the depth of the bass was a little more noticeable and textured.

- But please remember, a single set of cables cannot produce these amazing results.

- in my system ALL of my cables adopt the Helix Geometry and use the Neotech wire!

But were they that much better than the VH Audio or Mundorf wire?

With wires and cables of this caliber you can discern the tinniest improvements or changes.

I now list three wires on this site - Mundorf, VH Audio and Neotech, all of which are capable of achieving extremely good performance on any system.

They are quite different when it comes to the "extremely fine details" and will convey a slightly different sonic presentation.

Also, it could well be that it comes down to personal preference and component synergies.

My preference is for the Neotech wire in all of my cables, but individual preferences on other systems may required that a combination of these wires be used.

So from that perspective I am unable to recommend a specific wire, but in general, for the Interconnect Cables…

- Mundorf 18 gauge Solid Silver with1% Gold is very detailed with a smooth clarity

- VHAudio 18 gauge solid UP-OCC copper with AirLok insulation is perhaps a little warmer, with a little more presence

- Neotech 18 gauge solid UP-OCC copper with Teflon insulation improved performance (slightly) across the board

Burn-in of these cables is critical. Up to the 250 hour mark they can vary in their sound, sometimes harsh and bright and they sometimes presented an unbalanced nature to their image, in that some instruments sounded a little louder and more "forward" than they should i.e. they were not really an integral part of the overall image.

These anomalies are not uncommon during the burn-in process, but you do have to be patient and allow the process to proceed without interruption

See the links below for fabrication details

The previous adaptions to the Helix Interconnect Cables are courtesy of a long time contributor on the Audiogon Forum Member Name: Grannyring (i.e. Bill)

Bill has considerable experience with DIY cables and made me aware of the Schroeder Double Shotgun approach and then went on to build several variations of his Schroeder adaption of the Helix Interconnect that has two wires for the signal wire and two wires for the Neutral Helix coil and reported very favourable results.

Needless to say, I had to try this for myself.

In addition to this, I had also been auditioning in great detail the use of an 18 gauge Solid Copper wire from VH Audio for the Signal conductor, which I now "generally" recommend in place of the Mundorf solid silver + gold wire I had previously favoured.

Both of these adaptions are now detailed on the Helix IMAGE Interconnect link below

And let's not forget the previous contributions courtesy of Ernst of Austria and Yordan & Evgeny of Bulgaria

Yordan and Evgeny have contributed with...

- the performance aspects of various wire types and metallurgy,

- discovered that the direction the helix coil was wound is critical - see Inside The Helix Geometry.

Ernst embraced the Helix design some time ago and has been experimenting with some different materials in order to improve on the performance of the Helix design with astounding success.

His first development was to eliminate the use of as many man-made insulation products (e.g. teflon tubing, expandable Nylon sleeve) used in the original designs.

His second development was to use balsa wood as the spacers every few centimetres in order to hold the signal wire in his speaker cables in the centre of the Helix coil.

The reward for Ernst’s endeavours was a significant improvement is sound quality with respect to improved details, clarity, dynamics, bass control and depth and a significantly wider and deeper image.

His approach considered the Dielectric Constant (D.C.) of various materials.

- Dielectric constant, property of electrical insulating material (a dielectric) equal to the ratio of the capacitance of a capacitor filled with the given material to the capacitance of an identical capacitor in a vacuum without the dielectric material.

Ernst found that using materials having a lower D.C. than that of the insulation, expandable Nylon and heat shrink originally used to centre the signal wire in the Helix, significantly improves on the performance of the cable.

- Since air has a D.C. = 1.1, placing the spacers at intervals on the signal wire improved signal transfer even further.

My “adaptions” of the cables built by Bill, Yordan, Evgeny and Ernst, can be found in the following construction details...

The latest design of the Interconnect Cable...

The new USB Cable...

The latest design of the Speaker Cable...

The latest design of the Power Cable...

I am currently using cables that have been modified as in the links above and can report that the modifications have resulted in significant and easily discernible audible improvements over the older design. Improved clarity, sense of space, dynamic performance and improved details are the benefits observed by the changes in insulation.

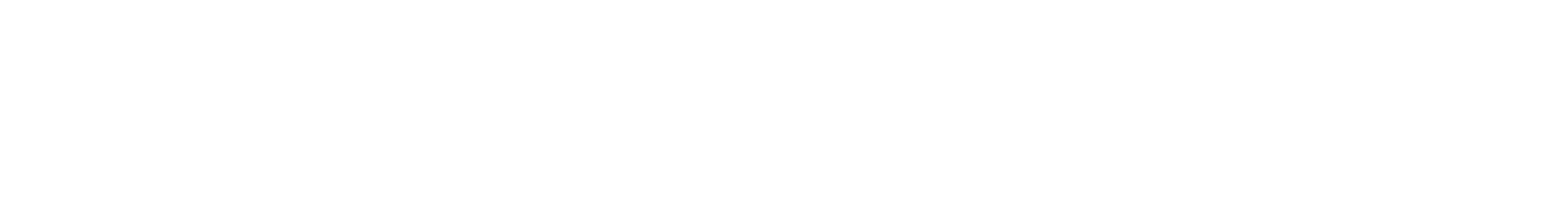

I have listed a few options of wires that can be used for the signal and neutral wires, but the digram below shows which wires I use and for which components

The original helix design concept was to eliminate the parallel conductors commonly used in conventional cable architectures in order to minimizes the noise, proximity effect and Skin effect to imperceivable levels, improving clarity and dynamic performance of the interconnect.

Since those early days, developments include the selection of advanced wire metallurgy, gauge of wire best suited to the task at hand and types of insulation in order to reduce noise to a minimum, which brings us to this moment in time.

The instructions on this web site demonstrates how these cables can be fabricated in the easiest and most cost effective manner in order to achieve extremely high levels of resolution that competes with the very best commercially available products for a fraction of the cost.

Will there be any further updates - probably, because there is always someone, like Bill, Ernst, Jordan and Evgeny that is looking to improve on the capabilities of “The Helix” cable geometry.

“The HELIX IMAGE” - these cables now convey the most realistic and compelling image I have ever observed in any system

The level of detail and clarity, together with precise location of performers and an image that envelopes the listener is stunning

I would like to thank and congratulate Bill, Ernst, Yordan and Evgeny on these exciting new developments.

The stunning performance of Helix Cables of today are due to all that have contributed. including earlier contributors such as Todd (US) for developing the first bi-wire version of the Helix speaker cables, Ghislain (Canada), John (USA) and many others.

WARNING: HELIX Speaker cables WILL NOT work with amps of a fully balanced "Symmetrical" design, such as the the Vitus and some fully balanced designs from Musical Fidelity. they will not harm the amp, they just sound bad

If you have any further questions on these upgrades just drop me a line.

Regards - Steve

The HELIX USB Cable

Please Note: this cable does not include the conductor that carry USB supplied power.

- adding a separate cable for this purpose is detailed below

The fabrication of this cable follows the same approach used in the construction of the analogue interconnects and has…

- A twisted pair that carries the D+ and D- digital signals

- NOTE: using the D+ and D- is a differential signalling technique as used in XLR "Balanced" cables.

- A Helix Neutral conductor that is connected to the neutral side of the circuit

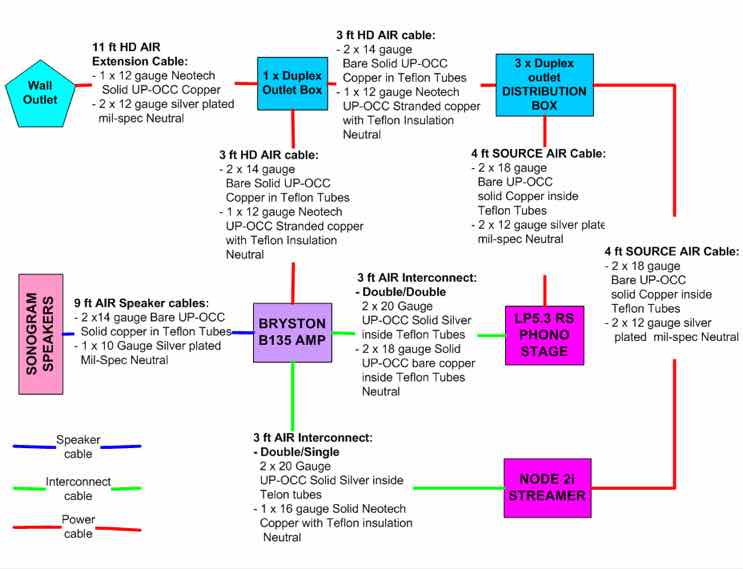

Unfortunately, the TYPE A and TYPE B connectors used are really designed for 24/28 gauge wires and definitely NOT designed for use with the Helix Coil, i.e. without a simple modification

Simply remove the Cable clamps as in the diagrams below

TYPE A USB CONNECTOR

BEFORE AFTER

TYPE B USB CONNECTOR

BEFORE AFTER

NOTE: When attaching the wires please ensure you observe the correct pin connections

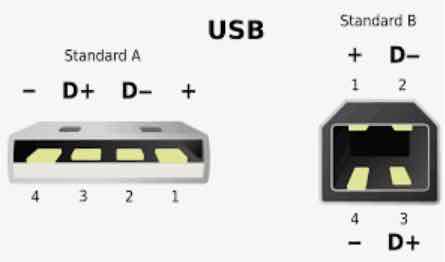

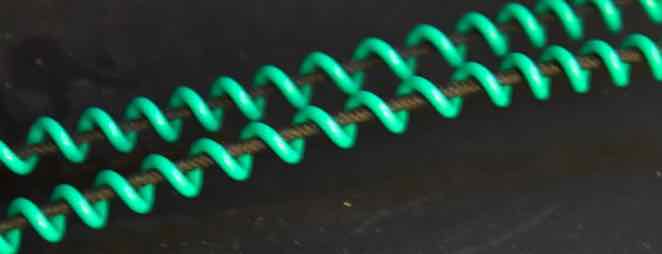

Next, construct the D+ and D- Twisted Pair using a "short twist" as in the image below

- i.e. 3 twists per inch (or per 25mm)

You can use the same 18 gauge wire as used with the Analogue Interconnect, but since there is very little space in the USB connectors the problem of wires shorting out requires extremely precise soldering

The recommended wires for this cable is:

- 18 gauge UP-OCC Solid Silver with AirLok insulation from VH Audio for the signal wire, or

- 18 gauge UP-OCC Solid Copper with AirLok insulation from VH Audio

- 16 gauge Silver Plated Mil-spec for the Helix Neutral (i.e. as used on the Analogue Interconnects)

Please note that either of the signal wires above will perform to a very high level, but for the very best performance, the solid silver wire is preferred

Insert the twisted pair into a piece of cotton tubing with heat-shrink (with adhesive) at each end to hold it in place

Insert that assembly into the Helix Coil and attach the connectors…

Connect one end to the Type A connector.

Stretch the Helix coil to the length of the signal wires

Connect the other end to the Type B connector.

Here is a view of the wires connected to the top of the Type B connector

And a view of the wires connected to the Bottom of the Type B connector

Once the wires are soldered in place, Fix the metal housing in place using a hot glue gun.

Be sure to cover the solder joints with hot glue, so as to insulate them from the metal housing

Hot glue the metal cap into place, again covering any solder joints with the glue.

NOTE: Add a little more hot glue to secure the cable assembly to the connector, for strain relief

Do this for both Type A and Type B Connectors

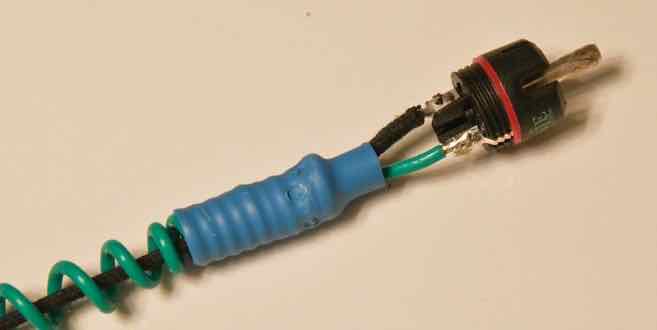

Place two pieces of Heat-shrink (with adhesive) over each connector assembly and the Helix coil to provide additional "strain relief"

NOTE: ensure the Heat Shrink extends onto the Helix Coil by approximately 1.5 inches.

- This prevents the cable from bending and breaking the the delicate solder joints.

And VOILA ! - you have a high performance USB cable

PLEASE NOTE: Before connecting any cable to a component be sure to test the continuity of the pins of each connector

How do I add the Power Supply Wires?

If you would like to add the wire that will provide USB power to the connected device as follows…

- Once the USB connectors have been soldered to the D+ and D- twisted pair BUT before the hot glue has been applied to the connectors

- Cut a length of 18 gauge wire slightly longer than the length of the USB cable

- insert the wire into a piece of braided screen tube (approximately 1" shorter than the piece of wire)

- Then insert the wire and the braided shield into a piece of expandable nylon sleeve (for insulation) and secure with a piece of heat shrink at both ends

- PLEASE NOTE: - the screen is NOT connected to either of the USB connectors

- connect one end of the power wire to the +ve power pin of one connector

- "loosely twist" the power wire assembly around the Helix coil ( i.e. about 4 times around for a 3 ft cable) - this keeps the +ve wire close to the cable

- solder the other end of the +ve wire to the other USB connector

- hot glue the metal casings onto the USB onnectors as detailed above

- Add the two pieces of heat-shrink (with adhesive) over the connector, helix coil and the +ve wire with screen (as shown above)

Audiogon member Grannyring has reported that the Solid Silver conductor from VH Audio provided the highest quality he has ever heard from his USB DAC.

The "HELIX IMAGE" Speaker Cable

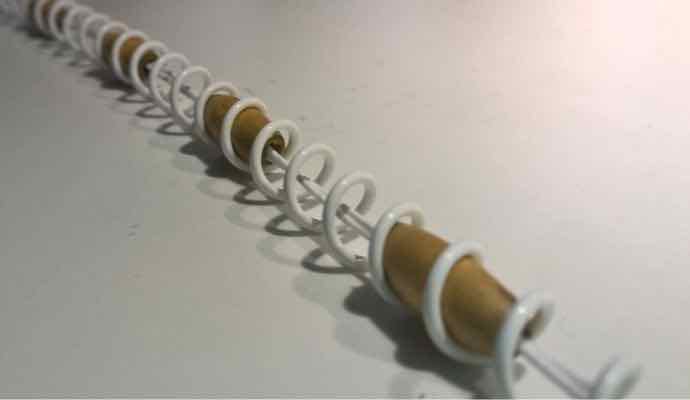

Since their introduction, The Helix Speaker Cable has undergone a significant change to their design, by enlarging the diameter of the Helix and adding wooden beads to centre the signal wire within the helix.

So what makes Helix cables work?

The premise behind its helical geometry (or architecture) is eliminating parallel conductors, since...

- if two parallel conductors are in close proximity for an extended distance, and current is passed down them, then noise & distortions will occur within them.

- Speaker cables have to deal with larger voltages and currents and can be subject to more severe distortions than Interconnects, however, their signal is not amplified like the signal in the interconnect and relative to the actual signal the distortion is quite small

Why would this matter? Isn’t the neutral is effectively connected to the “ground” ?

Well, the neutral conductor is actually connected to the neutral side of the circuit of the amplifier.

- Any noise that permeates through the neutral side of the components circuit, will have a negative impact on the amplified signal, resulting in distortions in the signal, which is output to the speakers.

It get’s pretty complicated ...

For more information on cable design issues please read the three articles below that talk about the many problems that challenge cables builders.

They will provide a great deal of insight into the many parameters and design techniques employed to build cables that excellent in their performance.

https://www.psaudio.com/article/cables-time-is-of-the-essence-part-1/

https://www.psaudio.com/article/cables-time-is-of-the-essence-part-2/

https://www.psaudio.com/article/cables-time-is-of-the-essence-part-3/

So, how do Helix cables prevent that from happening?

In the Helix design, the neutral conductor is wound around the signal conductor, so the neutral is NEVER parallel to the signal wire.

This minimizes -

- induced noise

- Proximity Effect

- Skin Effect

- Rise Time and Decay Distortions

- Minimize Dielectric influences by using only single conductors for the signal and neutral wires

VOILA! - most “cable related problems” are eliminated !!!

(pretty much)

But in addition to that, the Helix acts as a Faraday Cage surrounding the signal wire, which impedes the effect of external RFI/EMI on the signal.

This makes the Helix Geometry one of the most noise-free cable geometries available.

If applied to ALL cables in a system, the resulting level of fidelity you probably thought could only be attained by having components costing considerably more, is only constrained by the components themselves and todays components are actually extremely good.

What will you hear? - for me the most noticeable improvement were the details that came to life in the venue acoustics, i.e. the echoes and reverberations that surround each artist and instrument.

At first, it can sound as though you have an echo problem in the room, but I have several tracks where there are no reverberations, so playing those confirmed my room acoustics were perfectly fine.

Other attributes that are clearly audible include clarity, neutrality, dynamic performance, bass depth and control.

But one effect that took a while for me to realize just how much it effects the sound is an audio effect called phasing.

Phasing controls the placement of instruments and artists in three ways.

- Their location within the width and depth of the image

- Their location outside of the speakers

- The appearance of the “projection” of sound around (even behind) the listener e.g. like surround sound

We all know if you connect the speakers out of phase the image becomes muddled and the bass performance drops off.

But varying the phase by small amounts can move the position of instruments and artists within the image. The noise impacts the phase of the signals of both channels differently, resulting in an inaccurate image.

Since the Helix Geometry eliminates most all of the noise created inside the actual cable - you will notice an incredibly precise placement of instrument and artist within the image AND an incredibly large image that melts the boundaries of the listening room and envelops the listener.

Now the speakers are truly “invisible”

PLEASE NOTE: Your system will probably not achieve its full potential by installing just one set of helix cables...

ALL cables have to be built using the helix geometry !!!

How To Make Them...

FIRST: determine the “Direction” of the Helix - see Inside The Helix Geometry.

Here are the parts...

- Neutral Conductor: 10 gauge silver plated Mil-Spec wire for the neutral from TAKE FIVE AUDIO (TFA)

- Signal conductor: PLEASE SEE NOTE-A below

- One five foot 1/2” (12mm) fibreglass rod from home depot

- One set of KLEI™Classic Harmony Banana plugs

- 10mm diameter wood beads available from Ebay - i.e. 6 - 7 beads per foot of cable + 10 beads for each end

- like these 20x 25x10mm long oval natural wooden unpainted wood beads diy jewelry making

The neutral conductor should be 2.5 times longer than the signal conductor, although you can experiment with this ratio

So for one 10 ft cable PAIR you need

- 20 ft of signal conductor i.e. 10 x 2

- 50 ft of neutral conductor.

NOTE-A: The Signal Conductor

- For the budget conscious - you can use a 16, 14, or 12 gauge silver plated Mil Spec wire from TFA

- personally i prefer the 14 gauge, but some people prefer a heavier gauge.

- if you are using a high powered amp (i.e. > 600 watts) and low impedance speakers (2-4 ohms) you might want to move to a larger gauge

My favourite wire provides a more detailed and dynamic presentation is a single strand of Neotech 14 gauge UP-OCC Solid Copper with Teflon.

Another very good conductor is 2 x 18 gauge UP-OCC copper with AirLok insulation from VH Audio for a more "relaxed" presentation

Tips on Installing the Banana plugs

Please review this link…

http://www.image99.net/blog/files/tag-banana-plugs.html

Please note: the images below may not reflect the wire identified above.

Cut two equal lengths of the neutral conductor - this should be 2.5 times the length of the signal conductor

Put a very tight 90 degree bend in the conductor and tape to the fibreglass rod

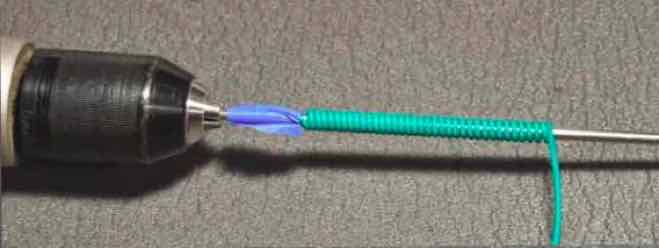

Place the end of the fibreglass rod into the chuck of a variable speed drill

Slowly wind the conductor onto the rod

Once the other end of the conductor is reached - leave 6”-8” of straight conductor

For the signal conductor…

- If you are using a single strand of wire, simply space the beads on the wire see

- If you are using the 2 stands of 18 gauge Solid Copper, twist the strands in a gentle twist - one twist every 4-5 inches

Slide the beads onto the signal conductor and space them evenly along the entire length leaving an 6-8 inch length of wire for connection to amp/speakers

I generally leave a 1.25" gap between the beads

Please note: The white beads are simply for clarity in the photo

The 5 centre (White) beads are NOT glued to in order to maintain flexibility

Where the signal wire comes out of the coil I use 7 beads together to prevent the coil touching the the signal wire where it exits the coil

i take this approach at both ends of the cable to allow connection in either direction

I use a very small dab of glue from a hot glue gun to stop the beads from slipping out of position

I use a small piece of Heat shrink tube at the ends of the wire to provide a support.

Insert the signal wire with the beads in the helix coil

TIP: to make this job easier tape a spare bead at the end of the wire - it allows the wire to be pushed freely through the helix

Attach the connectors of your choice - in my case I prefer bananas - Voila!

I highly recommend the KLEI™Classic Harmony Banana Connector/Adaptors because as you will read, they are exceptionally good and elevates the performance of these cables to a whole new level

These cables provide an extremely high resolution listening experience on all systems - i.e. once burned in

They have low levels of capacitance and inductance, so they are perfect for most systems, especially high current solid state designs.

Please allow 150 hours burn in before making any judgement as to their abilities.

Please note: you are free to try whatever conductors you think might work - but two the conductors identified above provide exceptional performance and value.

If you are thinking that 14 or 15 gauge is too thin to produce an excellent bass performance, I would suggest you try them first. I recommend a heavier gauge wire if the cable is connecting low impedance speakers (e.g. 2 or 4 ohms) to a high powered amp (in excess of 200 watts)

You will find the characteristics of the cables change during burn-in

- they will sound very good at first

- after around 12 hours their performance will degrade - bass will fall off and some distortion will occur

- after 30 hours they really start to shine

- by 150 hours they sound exceptional and will continue to get better

They provide exceptionally detailed and a well controlled deep bass performance

The clarity of these cables is superb, as is the dynamics and imaging

Total cost for a 10 ft pair is around $200 US. (i.e. depending on the wire used)

I have compared them to cables costing upwards of a couple of thousand dollars and they are superior across the board.

Hard to believe? Well, if I hadn’t heard it for myself I wouldn’t believe it either!

When I built these cables I was actually not expecting much in the way of improvement over my existing cables, which were on the pricey side and excellent performers

I thought they might come close to their level of performance - BUT...

I was Blown Away!!!

But REMEMBER: any system will not achieve its full potential by installing just one set of helix cables...

For optimum performance - ALL cables must employ the helix geometry !!!

These cables are truly exceptional, from a fidelity perspective and from a cost perspective they are excellent VALUE!.

For Helix cable spec’s please see Its More Than Just Numbers - Isn't It?

I give them my “Best Bang For The Buck” award.

My Review System:

Custom built turntable with a Soundsmith Denon DL103 phono cartridge mounted on an Audiomods Arm with one piece silver litz harness + KLEI Absolute®Harmony RCA’s

Simaudio MOON LP5.3 RS phono stage

Bluesound Node 2 music server

NAIM 5i integrated amp (with passive pre-section).

Gershman Acoustics Sonogram speakers.

Give them a try - and - Enjoy The Music!

Give them a try - and - Enjoy The Music! ![]()

Helix Geometry Adaptions:

The development of these cables was something of a collaborative effort. it all started when I responded to a post on the Audiogon Cable Forum by Audiogon member Toddverrone (Todd)

Todd was already familiar with the Helix design since had had already made a couple of my Helix power cables.

We discussed possible approaches, but since I had not actually made a set of Speaker Cables I figured I’d better “Walk the Walk”

And so, the Helix Speaker cables (of the above design) were “born”.

However, since Todd’s speakers were configured for a bi-wire/bi-amp approach he wondered if there was a viable Helix Bi-wire solution in a single cable.

Taking the design above, I modified it in the following manner to incorporate two sets of conductors (LF and HF) into a single cable as follows:

- the two positive conductors would be wound around the fibreglass rod and then straightened out by hand, but leaving the kinks in the conductors in place.

- Each conductor is wound in opposite directions in order to stop them from being able to touch continuously to prevent EMI contamination.

- the two signal conductors would be placed inside two (LF and HF) helix neutral windings, but each neutral would also be wound in opposite directions - again to minimize EMI contamination.

- The net result is what Todd referred to as - one “bad-ass” design

- Perhaps I should name it the - Bad-Ass Helix Bi-Wire ?

As part of the process, Todd had first built a prototype along the lines of the original design above, in order to gauge what the single wired cable would sound like.

This level if fidelity could then be used as a benchmark for comparison to the Bi-wired version.

Todd also used a high grade silver plated copper conductor for the bi-wire version

Final conductor details:

Signal Conductor

- One LF 12 awg conductor and One HF 14 awg conductor with a “kinky helix” wind in opposite directions,

- both are silver plated copper in ptfe from take five audio.

- Dual LF 12 awg silver plated copper conductors in ptfe for the inner helix

- Dual HF 14 awg silver plated copper conductors in ptfe for the outer helix

- The 14 gauge was the outer Helix because it is easier to wind

See pictures below...

And The Verdict?

Todd’s Feedback...

- So far, they are superb!

- The same black background as the single helix with cat 5, but more clarity from top to bottom.

- There's not more bass, it's just a bit tighter and cleaner.

- The mids and highs have greater clarity and come further out from the background, with better separation of sounds.

So there you have it! - Seems like Todd is pretty happy with his creation.

Whether single wire or bi-wire these cables provide extremely good fidelity, dynamics and bass performance. But please remember to allow them to burn-in for around 200 hours before serious listening.

A special thanks to Todd for taking on this difficult task - winding those helix neutrals can be quite tiring on the hands

I give them my “DOUBLE Best Bang For The Buck” award.

Give them a try - and - Enjoy The Music!

Give them a try - and - Enjoy The Music! THE HELIX IMAGE" Power Cable

I started looking at cable architectures a while back, initiated by an experience with a home lighting repair.

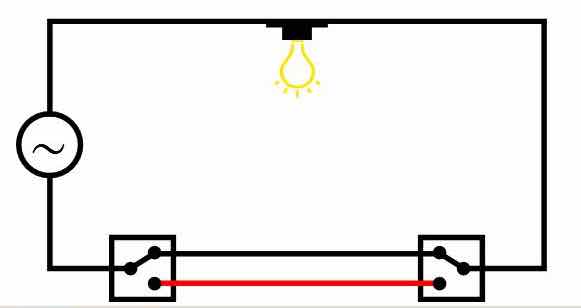

I was installing a new two way switch on a hallway light, the type with a switch at each end of the hallway (see diagram below). I decided to play it safe and use my multimeter to verify the open/closed position of the switches.

With the switch in the OFF position everything checked out, but with the switch in the ON position I found that there was a reading of 42 volts on what was supposed to be the "dead conductor" i.e. the red conductor in the diagram below.

I subsequently found articles on the web which verified that in this particular situation it is common for one of the conductors in standard household power cable to register an "induced voltage".

In the case of “conventional” power cable architectures, the live conductor and the neutral conductor tend to be side by side in extremely close proximity for the length of the cable, so is it reasonable to assume that noise will be induced between the conductors in a power cable?.

Would “noise pollution” also be present on the ground conductor, which, and depending on the design of a components circuit, might also have an adverse effect on sound quality?

Additional research revealed even more to consider regarding good cable design...

For more information on cable design issues please read the three articles below that talk about the many problems that challenge cables designers.

They will provide a great deal of insight into the many parameters and design techniques employed to build cables that excellent in their performance.

The articles are specific to Interconnect and speaker cables, but much of the theory also applies to power cables

https://www.psaudio.com/article/cables-time-is-of-the-essence-part-1/

https://www.psaudio.com/article/cables-time-is-of-the-essence-part-2/

https://www.psaudio.com/article/cables-time-is-of-the-essence-part-3/

The premise of the helical design concept eliminates the parallel conductors which minimizes cable issues to imperceivable levels!

BONUS! - the Helix acts as a Faraday Cage just for the signal wire!

But First My Disclaimer:

DO NOT attempt any of the assemblies detailed below unless you are an experienced Electrical Professional OR Electronics Hobbyist - otherwise consult a technician!

YOU ARE RESPONSIBLE: for following local electrical codes. Failure to do so may result in personal injury, damage to equipment, or power cable failure which can result in fire.

YOU ARE RESPONSIBLE: for ensuring the cable selected is suitably rated for the power requirements of the component(s) it will be attached too !

YOU ARE RESPONSIBLE: for ensuring the IEC/Mains connectors are installed observing the correct polarity !

- failure to do so can result in poor operation, component failure or electric shock.

YOU ARE RESPONSIBLE: for ensuring the dielectric strength of the insulation on ALL conductors used, meets or exceeds local codes!

e.g. In North America - 600v at 200 Celsius for 120v 50/60 Hz supply

These Power cables are only to be used for Home Audio Purposes and must not subjected to harsh environments and frequent handling, which generally require additional protective coverings.

The materials mentioned below comply with most codes for NORTH AMERICA ONLY!

Electrical codes in other countries may require the selection of different materials, therefore YOU ARE RESPONSIBLE for following those local electrical codes.

YOU are responsible for ensuring “power related” assemblies are safe to use!

So what’s changed???

Since there is very little actual difference from a geometry perspective between the previous versions of the power cable and this renamed version I considered not assigning a new name, but then I realized

- the expandable sleeve over the cable assembly has been removed

- the expandable sleeve on the Live Wire has been removed

- a new Live Conductor option is now used, which improves the resolution performance of the system components

Why remove the sleeve?

The nylon sleeve and heat shrink increases the Dielectric Constant (D.C.), which impedes cable performance

- If you prefer to use a sleeve I would recommend a Cotton Sleeve over the man made fibres

And so the Power Cable inherits the HELIX IMAGE nomenclature !

What size wire do you recommend for various components?

I have found that using a 12 gauge live Conductor built from four 18 gauge solid copper wires will suffice for the most demanding components (e.g. amps up to 600 watts).

You might think a 12 Gauge cable is capable of handling much more that 600 watts, HOWEVER, transient peaks in the music can result in very high instantaneous current demands. This cable has been designed to accommodate a significant amount of "headroom" in order to handle those peaks without compressing the signal, so I conservatively rate its use up to 600 watts.

However, since you will NEVER drive a high output amps to their max, these power cables can be used with higher wattage components up to 1000 watts.

For Source components up to 40 watts I have added construction details further down this page that uses an 18 gauge solid silver wire that provides exceptional performance, But after some testing using the 18 Gauge Solid Copper it would appear that the copper performs equally as well.

You can use 18 gauge wire for most lower powered Source Components up to 40 watts with additional cotton sleeve as detailed below.

If you component draws between 40-80 watts, then use two strands of 18 gauge wire/

Materials...

The materials listed below will build a 5ft power cable that is suitable for use with Power Aimplifiers rated up to 600 watts.

- LIVE Conductor: Either…

- One single strand of 12 gauge Neotech UP-OCC solid copper (my preference) or…

- 4 strands of 18 gauge OCC Solid Copper with AirLok insulation for a more relaxed presentation

- However, if you want a more budget oriented power cable you can use either

- 12 gauge Duelund wire with the Polymer insulation (NOT the Cotton/Oil insulation)

- OR 12 gauge Mil-spec wire from Take Five audio

- NEUTRAL Conductor: 30 feet of stranded Mil Spec 12 AWG Silver Plated Copper Wire, Cryo Treated, Red - available from Take Five Audio (TFA)

- GROUND Conductor: 15 feet of green 12 gauge mains copper wire from Home Depot

- 4" of 3/4" or 1” black Heat Shrink sleeve

- 2" of 1/8" black heat shrink sleeve with adhesive

- 6 ft of 1/8" diameter cotton sleeve - when installed the sleeve expands, which makes it shorter

- 1 Pair of SONAR QUEST CRYO Ag Audio Grade Silver plated IEC plug + US main plug

- eutectic solder suited for electronics use - or WBT 4% silver solder can also be used

- 6 x 10-12 gauge copper spade/fork connectors

- For Spade/Fork terminals take look at the Grainger Web site and in their options check box select TERMINAL TYPE: Standard, WIRE RANGE: 12-10 gauge, INSULATION TYPE: Bare and SEAM: Butted

- Fork Terminals - Spade Terminals - Grainger Industrial Supply

- 1 - 5/16” (7-8mm) diameter fibreglass rod 4-5 ft long - available from Home Depot

The Sonar Quest connectors have heavy Silver plating on pure copper contacts that provide excellent clamping and transmission of electrical current - available from ebay

I use an approximate ratio of 3:1 of Ground/Neutral:Live conductor

e.g. for a 5ft power cable I use 15ft of Ground and 30ft of Neutral Conductor

How To Make Them...

To determine the “Direction” of the Helix - see Inside The Helix Geometry.

The Neutral Conductor...

The Neutral Conductor is made from two lengths of the Mil Spec 12 AWG Silver Plated Copper Wire listed above.

Why two pieces? - this effectively make the neutral wire a 9 gauge conductor, which I have found performs much better than a single 12 gauge wire, resulting in faster dynamics, better bass performance and control and more natural imaging.

Cut the 30 ft length of wire into two equal length pieces.

On the 5/16” rod, wind the neutral conductor in a helix configuration, space the windings about 1/4” apart and remove from the rod.

Repeat the winding process with the second piece of wire.

With the second coil of wire still on the rod...

- Attach the first coil to the second coil with a 10 gauge spade connector

- Wind the first “coil” of wire between its windings as shown below

Remove the two “intertwined” coils from the rod

The Ground Conductor...

On the 5/16" rod, wind the green GOUND conductor in a helix configuration, space the windings about 1/4” apart and remove from the rod.

Then place the two red conductors back on the rod and add the coiled ground wire just as you did the second neutral conductor (above)

The Live Conductor…

For heavier current applications, like amps, power distribution panels and extension cables (up to 600 watts) I now use one strand of 12 gauge Neotech UP-OCC solid copper with Teflon insulation. Please note that this wire is very stiff and as such it should NOT be used for power cables that are flexed frequently.

For a more "mellow" presentation you could use 4 strands of 18 gauge solid OCC copper from VH Audio.

If you feel you need higher current carrying capacity, just add another strand of the VH Audio wire

To fabricate the live conductor using 4 strands of VH Audio Solid copper…

- First, cut 4 pieces of wire to the length you require + 1" to allow for trimming

- strip 3/4" (15mm) of insulation from each wire

- twist together tightly using pliers

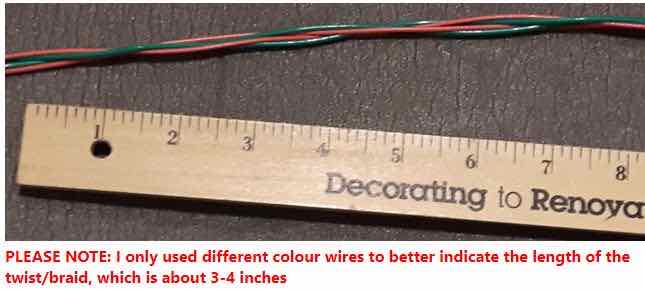

- then braid the 4 wires in a "relaxed braid" as shown in the photo below

- when you get to the end of the braid, strip 3/4" (15mm) of the insulation and twist the 4 wires tightly together

- insert the braided wires into the cotton sleeve and secure each end with a piece of Heat Shrink

Here is a photo to show the "relaxed braid" I currently use.

Using a relaxed braid allows the cable assembly to flex more easily

Regardless of which wire you select for the live conductor

- Trim one end of the "conductor assembly" to the length of the spade terminal collar

- Attach a 12/10 awg spade connector on one end of the Live conductor assembly, crimp and solder in place.

- Thread the Live conductor assembly through the centre of the red & green coil(s)

- Trim and attach a second 12/10 awg spade connector on free end of the Live conductor, crimp and solder in place.

- Attach a second 12/10 awg spade connector on the two free ends of the neutral conductor, crimp and solder in place.

- Place 12/10 awg spade connectors on both ends of the ground conductor, crimp and solder in place

Cut two adequate lengths of 3//4" or 1” heat shrink tubing and place over each end of the cable assembly to provide a surface for the plug clamp on to.

Here are two of my power cables positioned on cable lifters...

NOTE: When Attaching the Sonar Quest connectors to the cable assembly...

PLEASE ensure you adopt the correct polarity - your life may depend on it!!!

Assembly Notes...

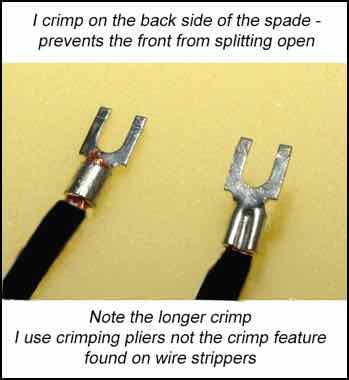

Why do I use spade connectors? -

- First, trying to attach the mains/IEC connectors to a large gauge cable is very difficult,

- More importantly - the spade connectors prevent detachment from the connectors in the event of unforeseen stress being placed on the connectors.

- I have also found that the spade connectors that are crimped and soldered actually improve sound quality.

For a more secure crimped joint, I always crimp from the back - as shown in the image below, which prevents the collar from opening.

I use pliers as shown in this image that applies an extended crimp along the whole length of the spade connectors collar

Cables that are more suited to source components can use lighter gauge conductors, but be sure to determine their power requirements and select a gauge that can handle it with headroom to spare.

Can you use other brands of IEC/Mains connectors?

Of course. Some people might prefer to use Furutech, or Oyaide high quality connectors.

Others may prefer to use something more reasonably price, like the Vanguard range of connectors.

I believe the Sonar Quest connector line provides exceptional sound quality for a reasonable price.

Power Cables for my Source Components...

Most “Source components” - like CD players, phono stages, DACs, etc.. draws significantly less power than amplifiers. They typically consume up to 40 watts

So, they do not require a 12 gauge power cable !

Most source components have a “less capable” power supply than amplifiers.

So their performance can be improved using a better “quality” power cable !

The following are details for building the HELIX IMAGE - SOURCE power cable as follows...

- The dual neutral wire is dual 14 gauge silver plated Mil-spec wire

- The ground wire is a single 14 gauge copper wire - I now use the Mil-spec wire - it retains the coil shape

- for neutral and ground wires - use a ratio of 4:1 neutral to signal to provide adequate helix coverage

- The Live conductor can be either an 18 gauge OCC solid silver wire from VH Audio - with AirLok mains insulation rated at 600v, or the more affordable 18 gauge Solid Copper wire with AirLok Insulation. If you are uncertain about the amount of power consumed by your component you can opt to use two strands of wire for the live conductor.

- NOTE: I have now tested both Silver and Copper wires with AirLok insulation on one of my source components and I could not tell the difference between the two. However, higher resolving components "may" provide slightly better results using the solid silver wire.

- you will also need cotton sleeve to space the live conductor more evenly within the Helix coil

First - the 18 gauge Solid Silver, or Solid Copper wire with the AirLok insulation can be purchased from VH Audio...

https://www.vhaudio.com/unicrystal-occ-silver-wire.html

https://www.vhaudio.com/unicrystal-occ-copper-wire.html

NOTES:

- The AirLok insulation of this wire is rated at 600V and has a lower Dielectric Constant than Teflon

- DO NOT use wire with cotton insulation - they are not rated for mains use in power cables

So - for a 5 ft cable you will need...

- 2 x 20 ft of 14 gauge Silver plated Mil-spec wire from Take Five audio for the neutral

- 1 x 20 ft of 14 gauge Silver plated Mil-spec wire from Take Five audio for the Ground

- 5 ft of UniCrystal OCC .99999 Silver Wire - AirLok Insulation from VH Audio (or the Solid Copper variant)

- 11 ft of 1/8” cotton sleeve

- 14 and 18 gauge Spade connectors - auto supply stores normally have very cheap spade connectors

- 2" of 1/8” heat shrink tube with adhesive

- some masking tape

- quality solder - I now use eutectic solder, but high content (e.g. 4%) silver solder can also be used

Follow the instructions above for creating the neutral and ground helix coils

The LIVE wire takes a little more effort...

Cut the cotton sleeve one inch shorter than the live wire and thread onto the wire

Using a small piece of masking tape, secure the cotton sleeve to the wire

Thread the second layer of cotton sleeve over the first layer

- this is more difficult, because you can only thread about 1” at a time

Note: the length of the second layer of Cotton sleeve expands, so a slightly longer length is required

Once complete REMOVE the masking tape !

Both ends should look like this...

Cut a 3/4” length of the Heat Shrink (with adhesive) and stretch one end, using a pair of needle nose pliers

Place the heat shrink over the double layer of cotton sleeve

Apply heat to secure the cotton sleeve to the wire with the heat shrink

- try NOT to burn the cotton sleeve

Thread the live conductor into the Helix neutral and ground assembly and attach the spade connectors to each end

Attach the mains connectors and you are DONE!

So why do they work?

The power supply of an amplifier tends to be very well designed and built, because of the power requirements at play, whereas the more affordable source components, tend to be built to a price point and therefore the power supply is very often not as “capable” as the rest of the circuit.

The rest of the electrical components are very often just as capable as those in the amp, but in operation, their performance is impacted by the inadequacies of the power supply when handling transient peaks in the signal

So if you use a very good power cable on a source component you can mitigate some of the inadequacies of its power supply.

The solid silver wire used for the Live conductor has an IACS rating of around 106% compared to copper at 100%

What is IACS? — it’s a measure of the conductivity of various metals relative to “Pure Copper”, a standard developed for copper wire producers, annealed copper having a rating of 100%

So the silver wire in these cables is able to respond more quickly to transient signal demands.

ALSO - the insulation on this particular silver wire has a dielectric constant (D.C.) of 1.4, compared to Teflon at 2.1.

The continual change in polarity of the alternating current charges and recharges the insulation much like the dielectric in a capacitor, which induces noise into the conductor. A lower D.C. reduces the amount of noise generated internally within the conductor itself.

However, solid silver wire is very expensive, and I am a frugal being, which is why I have only selected it for power cables that will be used only on my source components.

But you could use multiple strands of the solid silver wire for the live conductor to increase the current handling capability - e.g. 4 x 18 gauge strands would equate to a 12 gauge conductor

What improvements did I observe?

- There was a significant improvement in the details of “venue acoustics” - i.e. echoes and reverberations

- dynamics were noticeably crisper

- the image was noticeably larger front-to-back and there was more precision of artist location within the image

- there appeared to be more “air” around each performer

- clarity was improved, i.e. you could hear more of the fine details and layers within the music

I recommend making the single 18 gauge cables...

ONLY - if your component draws less than 40 watts - WHY?

The 18 gauge wire(s) is rated at around 1 amp - HOWEVER - transient spikes can result in significantly higher current draws, which can impact performance or even overheat the cable.

For components rated BETWEEN 40 - 80 watts - use 2 x 18 gauge strands (effectively 15 gauge).

FOR USE WITH AMPLIFIERS - you could use 4 X 18 gauge wire for the live conductor - that would effectively make it 12 gauge conductor.

Can I just Upgrade an existing 12 gauge HELIX Power Cable?

Yes - just replace the 12 gauge Live conductor with a single 18 gauge conductor

- HOWEVER - mark the cable in some way to identify that it has the small gauge live wire that is NOT suitable for amplifiers

NOTE: The 12 gauge wire used for the neutral and ground wire when upgrading a 12 gauge power cable in this manner, is NOT detrimental to cable performance if using the 18 gauge live conductor.

Using Helix Power Cables in a more "Demanding" Environment

Let's face it, power cables in an audio system "generally" sit at the back of the audio rack and DO NOT move, except for the occasional component swap or audition. It's not what I consider a dynamic environment. so the construction methods and materials above are "safe", but for this style of use ONLY!

But, if you are planning on using a HELIX power cable for other purposes, e.g. I use them on my guitar amps, then I would highly recommend adopting the following "adjustments" to the Helix designs above...

- ONLY USE Duelund 12 gauge with the PolyCAST insulation for the LIVE conductor - it can withstand much more flexing of the cable than the Solid Core wires recommended above.

- Ensure that the Neutral and Ground Helix Coils are held in place at each end of the cable with two inches of Heat-shrink (with adhesive) as in the image below

- Also, use an expandable Nylon Sleeve to protect the cable assembly from abrasions and secure at each end with a piece of Heat-shrink (with adhesive)

- Ensure the cable clamps on the connector plugs securely hold the cable in place

I use this style of cable on my guitar amps and I cannot tell the difference between the 12 gauge Duelund and the 4 x 18 gauge Solid Copper versions of the Helix Power Cable.

I will warn that even this version of the Helix power cable IS NOT SUITED (intended or designed) to be used in extreme rugged and demanding environments. such as a recording studio or a live performance ! However exercising a little care and performing regular inspections to assess whether damage has occurred, you can use this variant in an the more demanding environment such as this.

If you need a "REALLY HEAVY DUTY CABLE", then, The Helix IS NOT the cable you need, so get yourself a length of Furutech bulk mains cable, which is designed to be used in almost any environment.

The Journey...

I’m a frugal person with a distinct dislike of overpaying for something as simple as a piece of wire!

I started making my own cables many years ago from Bulk cable with reasonably priced connectors.

I first tried Furutech bulk cable and then stumbled upon DH Labs, which I believe offers similar performance for about 1/3 the price - how could you not like that.

I then investigated a braided architecture which proved very effective, even using plain old Romex house wire.

Finally, I tried the Helix Architecture, which has proved to be the best performing power cable architecture to date.

I have now implemented this architecture on all my cables that have anything to do with audio.

What do they sound like?

The “HELIX IMAGE Power Cable” is a high performance power cable that allows connected components to perform to the best of their abilities.

They assist components in delivering ultra fast dynamic performance, exceptional clarity, expansive imaging and a very deep and exceptionally well controlled and very natural bass performance.

How Long is the Burn-In Period?

It is imperative that these cables are allowed adequate time to settle and burn-in...

- they will sound extremely good on initial installation

- after about 60 hours they allow more of the micro details in the form of venue specific reverberation captured in live recordings, or applied by very talented sound engineers, to clearly be heard.

The end of the Road?

My hope is that this design will be embraced and enhanced by the DIY Community and encourage them to experiment with different conductor materials and configurations to tailor the sound to their own liking.

For Helix cable spec’s please see Its More Than Just Numbers - Isn't It?

My Review System:

Custom built turntable with a Soundsmith Denon DL103 phono cartridge mounted on an Audiomods Arm with one piece silver litz harness + KLEI Absolute®Harmony RCA’s

Simaudio MOON LP5.3 RS phono stage

Bluesound Node 2i music server

Bryston B135 Integrated amp.

Gershman Acoustics Sonogram speakers.

Give them a try - and - Enjoy The Music!

Give them a try - and - Enjoy The Music! ![]()

The "HELIX IMAGE" Interconnect

The “HELIX IMAGE Interconnect” represents the very latest developments in researching different wire types, geometries and materials.

The premise behind its helical geometry (or architecture) is eliminating parallel conductors, since...

- if two parallel conductors are in close proximity for an extended distance, and current is passed down them, then noise & distortions will occur within them.

Why would this matter? Isn’t the neutral is effectively connected to the “ground” ?

Well, the neutral conductor is actually connected to the neutral side of the circuit of both attached components.

Any noise that permeates through the neutral side of the components circuit, will have a negative impact on the connected components, resulting in distortions in the signal, which is ultimately amplified and output to the speakers.

Any noise in the signal conductor gets gets distorted even further through each stage and again amplified even further

In addition, parallel conductors are prone to Proximity & Skin Effects which alters the resistance of the conductor. affecting the transfer the signal

All of this impacts the phase between the left and right channels, which “smears” the mage.

The original helix design concept eliminates the parallel conductors and minimizes the noise, proximity effect and Skin effect to imperceivable levels, improving clarity and dynamic performance of the interconnect.

Since those early days, developments include the selection of various types of wire, gauge of wire and types of insulation, to bring us to this moment in time

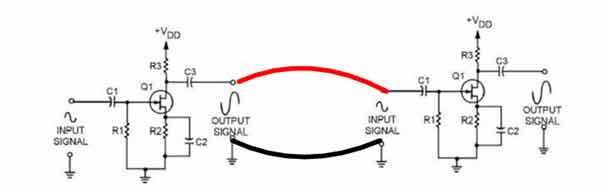

One other nice feature of the helical design is the neutral conductor, being wound around the signal conductor, becomes a very effective shield against external RFI sources - in effect is is a Faraday Cage surrounding the signal wire - because it is connected to “ground” ![]()

But Shouldn’t The Two Conductors Be The Same Length?

If you look at the “roles” the two conductors play from the perspective of an attached components’ circuit diagram it becomes clear that cable length is immaterial and they can be made from different materials and gauges.

- The Signal Conductor transfers the signal

- The Neutral Conductor completes the circuit, BUT, it also connects the neutral sides of the two attached components

- Any “noise” present on the neutral conductor impacts the operation of BOTH components.

For more detailed information on cable design issues please read the three articles below that talk about the many problems that challenge cables builders.

They will provide a great deal of insight into the many parameters and design techniques employed to build cables that excellent in their performance.

https://www.psaudio.com/article/cables-time-is-of-the-essence-part-1/

https://www.psaudio.com/article/cables-time-is-of-the-essence-part-2/

https://www.psaudio.com/article/cables-time-is-of-the-essence-part-3/

How To Make Them...

FIRST: determine the “Direction” of the Helix for the wire you will use - see Inside The Helix Geometry.

The Single Ended IC Design...

The parts list is reasonably priced between $180 - $250 CDN for a 3ft ( or 1 meter) pair, depending on the RCA’s and wire selected - and all other parts can be purchased from many parts providers on the web.

Granted, they are more expensive than most other DIY cables, but considering their exceptional sound quality and their ability to compete with many top of the line cables from established commercial brands, I believe this price range to be of excellent "value".

You can upgrade or downgrade these parts if you wish, but the parts listed will provide exceptional sound quality.

I use an approximate ratio of 3:1 of Neutral:Signal conductor

e.g. for a 3ft Interconnect cable I use 9ft of Neutral Conductor

The quantities listed is for a single Interconnect cable i.e. one channel - so double them for a stereo pair

- RCA Plug: KLE Innovations Absolute Harmony RCA Plugs (SOURCE: KLE Innovations or local parts sources)

- Neutral Conductor: 9 ft of Mil Spec 16 AWG Silver Plated Copper Wire Green Cryo Treated (SOURCE: TAKE FIVE AUDIO - TFA)

- Signal Conductor: 2 x 3 ft of 18 gauge Neotech UP-OCC Solid Copper wire with Teflon insulation, which is my preference.

- OR: for a slightly more mellow presentation use 2 x 18 gauge UP-OCC solid copper with AirLok insulation from VH Audio

- OR: 2 x 18 gauge bare Mundorf Solid Silver with 1% gold with cotton for a detailed, smooth performance

- WBT 4% silver solder OR Cardas Eutectic solder

Step 1.

I first wind the conductor around a 1/8" (3.5mm) metal rod. To assist with this I insert the rod into a variable speed hand drill and feed the conductor along its length.

Once wound, the helix can be removed from the rod.

Step 2

Insert the signal wire into the helix.

Space the windings over the length of the signal wire

You may need to tighten the helix by twisting it, about an inch at time, at each end to accommodate the RCA housing

Place a small piece of Heat shrink tube at the end to allow the two small set screws in the housing to grip the cable.

NOTE: the signal wire will touch the side of the Helix, but it does not appear to impact sound quality.

Step 3

Soldering the KLE Innovations needs a little care to prevent excess heat from damaging the plastic housing

I use a chassis mount RCA jack and insert the RCA base into it in order to wick away excess heat

I also use a little “rig” to hold the parts while I solder

I’ve found that it is easier if I first solder the signal wire to the RCA plug first, followed by the neutral wire

Install the housing of the RCA and tighten the screws and you are done!

Assembly of the “HELIX IMAGE DOUBLE/DOUBLE” interconnect...

This is the adaption that Bill (a.k.a. Grannyring on the Audiogon Forum) made me aware of. It was adapted from an approach known in audio circles as the "Schroeder Method" and Bill's adaption basically doubled up on both the Signal wire and the neutral wire of the Helix coil.

The construction approach is identical to the single wire IC above with the following changes…

THE SIGNAL CONDUCTOR:

I use 2 x 18 gauge Solid Copper wires from Neotech or VH Audio.

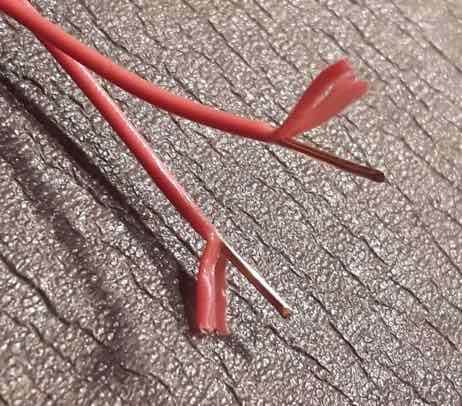

First remove about 3/8" (10mm) of the insulation from one end of the wire.

The best way to remove the insulation from the VH Audio Solid Copper wire with AirLok insulation is to compress the wire using the flat part of needle nose pliers and then splitting the insulation with my finger nail and then trim the insulation with cutters.

This technique prevents wire strippers from damaging the surface of the wire itself

Unfortunately, this technique does NOT work for the Tefon Insulation on the Neotech wire - you need wire stripers for that

Twist the bare ends tightly and then twist the two wires in a more "relaxed" manner i.e. one complete twist every couple of inches as shown below

Strip insulation from the other ends of the two wires, twist together tightly, solder each end and trim both ends to approximately 3/16 (5mm)

THE NEUTRAL CONDUCTOR:

To make the Double helix coil, strip about 3/8" (10mm) of insulation from the ends of two lengths of 16 gauge Silver Plated Mil-spec wire, twist tightly and solder

Then carefully form the coil using a variable speed drill by winding both wires.

Insert the Signal wire into the helix coil

Then just as with the single wire version

- Stretch the coil out to the length of the signal wire

- Place a piece of heat shrink on the end of the cable

- attach the RCA plugs

Please note: in the picture above I have used Cotton insulation - I have since found this is NOT required!

Assembly of the “HELIX IMAGE DOUBLE/SINGLE” interconnect...

In addition to the "Double/Double" I figured it was worth trying a Double/Single variant

- i.e. two signal wires with one Neutral wire for the Helix coil

So WHY all the different versions?

Well, I was pretty happy with the Single wired version, but Bill had reported significant improvement using the Double/Double approach.

My first thought was that I would just double-up the signal wire to see what kind of improvement I might achieve and leave the Helix Coil as a single wire

The results were very compelling and significantly better than the single wired version.

So now I had to try the Double/Double version in order to assess just how much better the Double/Double was than the Double/Single version.

CONCLUSION:

Well, the Double/Double is the best performer of the three, however, I found that the Double/Single provided about 65% of the benefit of the Double/Double.

What improved in both these cables over the single wired version as the precision and focus within the image, with a more realistic reproduction and a fuller sound

But the Double/Double just edged out the Double/Single version with a more realistic presentation.

So, for those that already have the single wired version - upgrading to the Double/Single version is a very easy process with minimal cost and effort.

For those of you that is just trying the Helix for the first time and want to minimize the expense, the Single/Single is still an excellent cable and the upgrade to the Double/Single is very easy.

But once you've sampled the Helix IMAGE, you too may be tempted by the Double/Double

But here's the weird thing - I actually prefer the sound of the Double/Single on my Phono stage and the Double/Double on my Streamer

So which "variant" is best for the components in your system may not be as simple as just making the Double/Double for everything.

Also, you might want to try different brands of wires for the signal conductor, e.g. some people prefer Mundorf Solid SIlver and others prefer Duelund tinned copper with Cotton Insulation - the choice is yours to make - there is no right or wrong

Did I try using a higher quality wire for the Helix Neutral?

- I only use the more expensive wires like Neotech or VH Audio Solid Copper wires for for the signal conductor - not for the neutral Helix.

- BUT: I did try the Duelund wire as the neutral on an interconnect, but I found it did not improve sound quality over the Mil-spec wire, so I continue to use the Mil-spec wire for the neutral. Others have also tried more expensive wires and observed the same results.

Can you use other brands of RCA?

NOT RECOMMENDED!

I recommend KLE Innovations Harmony RCA’s because of their stellar performance. Personally, I use the Absolute Harmony RCA because it is their best performer. I have used Furutech plugs, but the KLE Innovations product outperform the other RCA plugs I have tried, including Neotech Furutech and WBT RCA plugs.

Also, the properties of the KLEI Harmony RCA’s are very different from conventional RCA’s, such that they can be used on single ended SPDIF cables without experiencing the issues associated with conventional RCA’s not rated at the same impedance as the cable because their impedance exceeds 110 ohms.

e.g. “convention” states that a SPDIF cable should use an RCA plug of identical impedance

Primarily to reduce/eliminate internal “reflections” of the digital signal back down the cable

However, the KLEI Harmony RCA’S can be used on most digital cables regardless of the cables rated impedance value.

I also believe their higher impedance is responsible for their stellar analogue performance.

Can this cable be used for SPDIF purposes?

Absolutely! - it is an extremely adept SPDIF cable!

And I have found that the following cost saving adjustments do not impact SPDIF performance at all...

- KLEI Silver Harmony RCA plugs can be used in place of the more expensive Absolute Harmony RCA plug

- The Silver plated Mi-Spec wire is used for the signal conductor

To date, it is the best SPDIF cable I have used.

What do HELIX IMAGE Interconnects sound like?

The “HELIX IMAGE Interconnect” is a very highly resolving cable providing extremely good performance metrics with ultra-low distortion.

They deliver a completely “uncoloured presentation” with ultra fast dynamic performance, exceptional clarity, expansive imaging and a very deep and exceptionally well controlled bass performance.

They excel in the delivery of one of the most realistic and compelling presentations of live recordings I have observed.

- The delicate nuances pertaining to the acoustic reverberations of instruments and voice within a live venue are faithfully reproduced in the most minute detail, with a precision placement of musicians and their instruments within their own “virtual space”.

My system components are quite modest by today’s standards. However my cables are all excellent performers and they work in harmony with the components to achieve an excellent overall “system performance” that exceeds it’s price point by a considerable margin.

Will the “HELIX IMAGE Interconnect” perform well on all systems?

Based on feedback from people who have made them for installation in some quite varied systems, including all tube, tube hybrid and solid state, so I have no reason to believe their performance will be anything less than stellar on most systems.

However, each listener is unique and the synergy between components is varied, so you may need to adjust you particular cables to suite you YOUR ears. To that end I have provided the names of two wires that perform very well, but will allow you to personalize to your tastes.

Helix Geometry Adaptions…

The HELIX IMAGE Balanced (XLR) Interconnect

For a 3ft stereo pair:

- 2 pairs of Neutrik NC3FXX-HA Male/Female XLR Cryo Treated - with Silver Plated Pins ( SOURCE: TAKE FIVE AUDIO - TFA)

- Neutral Conductor: 18 ft of Mil Spec 16 AWG Silver Plated Copper Wire Green Cryo Treated (SOURCE: TAKE FIVE AUDIO - TFA)

- Signal Conductor: 12 ft of 20 gauge Duelund stranded Tinned Copper with Oil/Cotton insulation (Source: HiFi Collective)

- WBT 4% silver solder

The “standard” Balanced XLR IC design is “basically” the same as single ended design with a simple modification.

A balanced cable requires two signal conductors

- one for the positive signal

- one for the negative signal

- gently twist the signal wires together - 0ne twist every 5-6 inches

- Wind the neutral wire around a 6mm rod

- Insert the signal wires into the Helix

- add XLR connectors and Voila - you have a Helix XLR Interconnect cable

NEW DESIGN: The “HELIX IMAGE Mundorf (XLR)” Interconnect

Fellow DIYer, Yordan from Bulgaria, sent me this “upgrade” to the original XLR Interconnect design using wood beads similar in principle to the single ended design above, while incorporating Ernst’s approach of eliminating the use of man made sleeving/heatshrink and incorporating wood beads spaced along the signal conductor

The material choices, design elements and construction techniques of this cable makes it a worthy “HELIX IMAGE Mundorf” XLR Interconnect

if you wish to apply Yordan’s modifications and elevate your cable to the version shown below you will need ...

- Mundorf silver/gold wire, 0.5mm dia, SGW105 Teflon Insulated for the signal wire

- Mundorf silver/gold wire, 1mm dia, SGW110 Teflon Insulated for the neutral Helix

- 20 - 6mm diameter x 15 mm long wooden beads

- Yordan uses Oyaide SS-47 solder for the signal wires and Mundorf Supreme 105 silver solder for the neutral

And Then...

- wind the neutral conductor in a 8mm diameter spiral around an 8mm dowel/rod, wide enough to accommodate the 6mm diameter Beads

- Twist the signal conductors together - one complete twist every 2 inches (5-6 cm)

- Insert the twisted signal wires into the beads and use glue to hold the beads in place

- Insert the signal wire+bead assembly into the helix coil

- add XLR plugs and VOILA!

Yordan has also contributed considerably to the development of the Helix range of cables.

Yordan’s comments on the performance of the XLR cables...

“there was a jaw dropping effect - the sound is on another level”

The Journey...

I’m a frugal person with a distinct dislike of overpaying for something as simple as a piece of wire!

I started making my own cables many years ago, but many of those utilized bulk cable from companies like Van den Hul and DH Labs.

I then investigated some of the more recent cable geometries such as tight twisted pairs, braiding and helix geometries.

My primary goal along the way was to keep the cost of materials to a minimum whilst achieving extremely high levels of performance.

When I first tried the early CAT6 version of the Helix design it was quite clear that it was going to be a very adept performer.

This observation supported my belief that the Helix architecture (or geometry) was an extremely effective approach to achieving excellent cable performance.

The early versions utilizing CAT6 as the neutral conductor were very good - just not “brilliant”.

Evolution to the HELIX IMAGE and HELIX IMAGE Mundorf has been gradual with significant period of testing and redesign

The improvements achieved with the latest modifications, over previous versions, were so good that I decided that a new name was warranted - voila...

the “HELIX IMAGE ” and HELIX IMAGE Mundorf was born!

The result:

a cable that actually competes with some of the very best cables in the audio world!

C’mon, Really?

- OK, I’ll let you be the final judge, but after listening to many cables I believe this to be the case

How Long is the Burn-In Period?

It is imperative that these cables are allowed adequate time to settle and burn-in, which is typically >300 hours.

- they will however sound extremely good on initial installation

- they may exhibit some loss in volume and image focus after 3-4 days continuous use, but will return to normal by day 6-7

- they will sound exceptional after around 200 hours, but they will get even better after 300 hours

- I have also found ongoing improvements occur up to approximately 600+ hours in the earlier versions

- The use of cable cookers will expedite this process - start with 100 hours cooking + 100 hours playing

The end of the Road?

My hope is that this design will be embraced and enhanced further by the DIY Community, and encourage them to experiment with different conductor materials to tailor the sound to their own liking.

- Since the original posting back in 2015, I have exchanged email with several fellow Diyer’s that have contributed to the Helix design.

- Some people that have contributed to the evolution of the Mark VII design, including: Ernst (Austria), Yordan and Evgeny (Bulgaria), Ghislain (Canada), Todd (USA), John (USA) and many others.

For Helix cable spec’s please see Its More Than Just Numbers - Isn't It?

My Review System:

Custom built turntable with a Soundsmith Denon DL103 phono cartridge mounted on an Audiomods Arm with one piece silver litz harness + KLEI Absolute®Harmony RCA’s

Simaudio MOON LP5.3 RS phono stage

Bluesound Node 2 music server

Bryston B135 integrated amp

Gershman Acoustics Sonogram speakers.

Helix cables throughout

Give them a try - and - Enjoy The Music!

Give them a try - and - Enjoy The Music! ![]()

Other Helix Geometry Adaptions…

Audiogon Member Toddverrone has also tried these IC’s ...

The Parts List :

- signal wire: OCC solid silver 24awg in cotton. 3' per cable

- neutral: OCC solid copper 20awg magnet wire. 2 x 9' per cable

- connectors: KLE pure harmony solid silver

- the white tube is a foamed teflon flexible tube that i ran the signal through. it's pretty amazing. it doesn't kink at all. it's called hyperflex tubing from vh audio

Todd’s Feedback...

I’m still listening to them, but initial findings on the helix ICs are incredibly positive.

More of the helix magic: less noise, greater clarity, better separation of sound sources.

Good stuff!